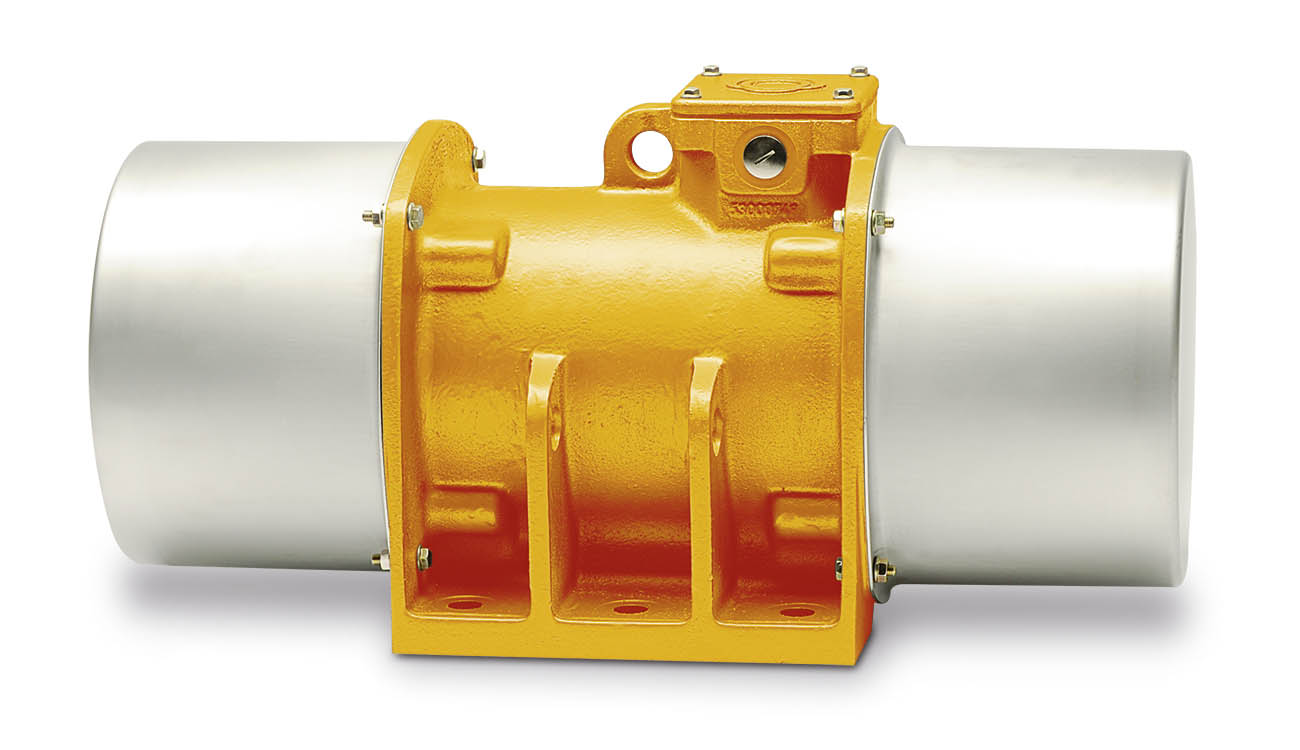

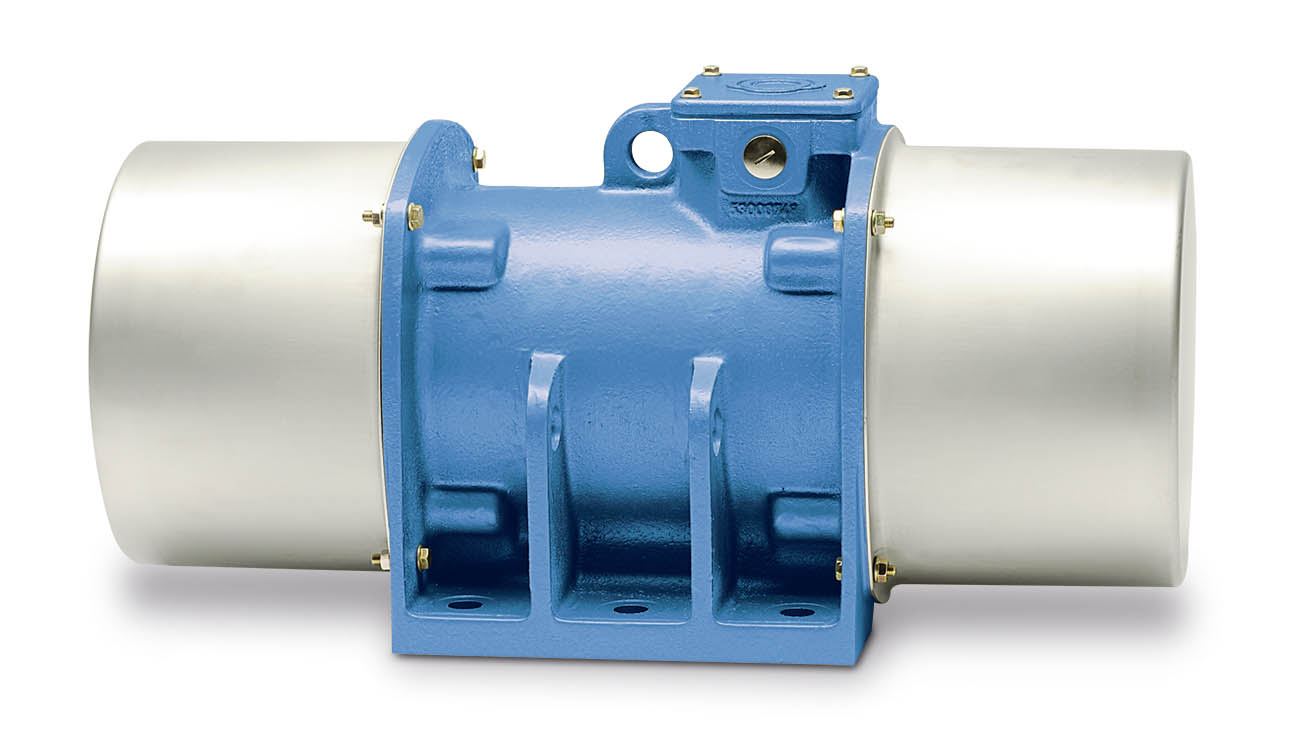

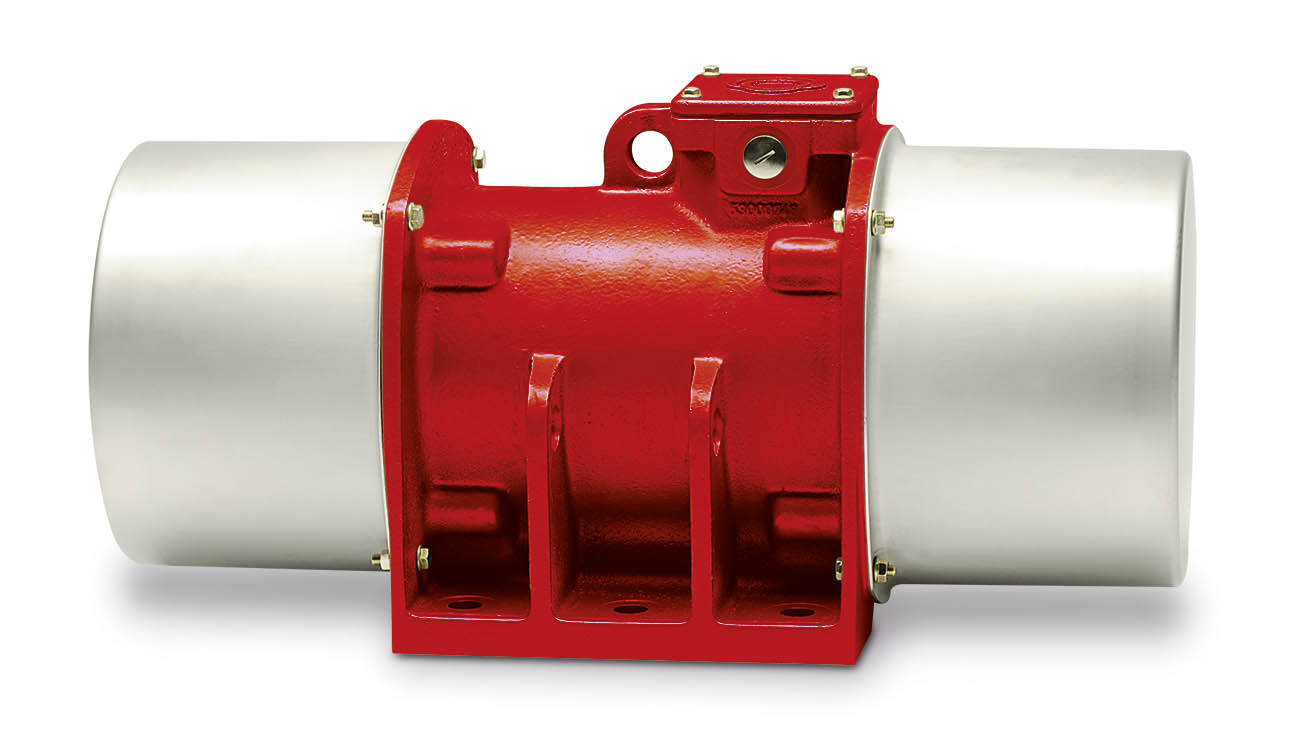

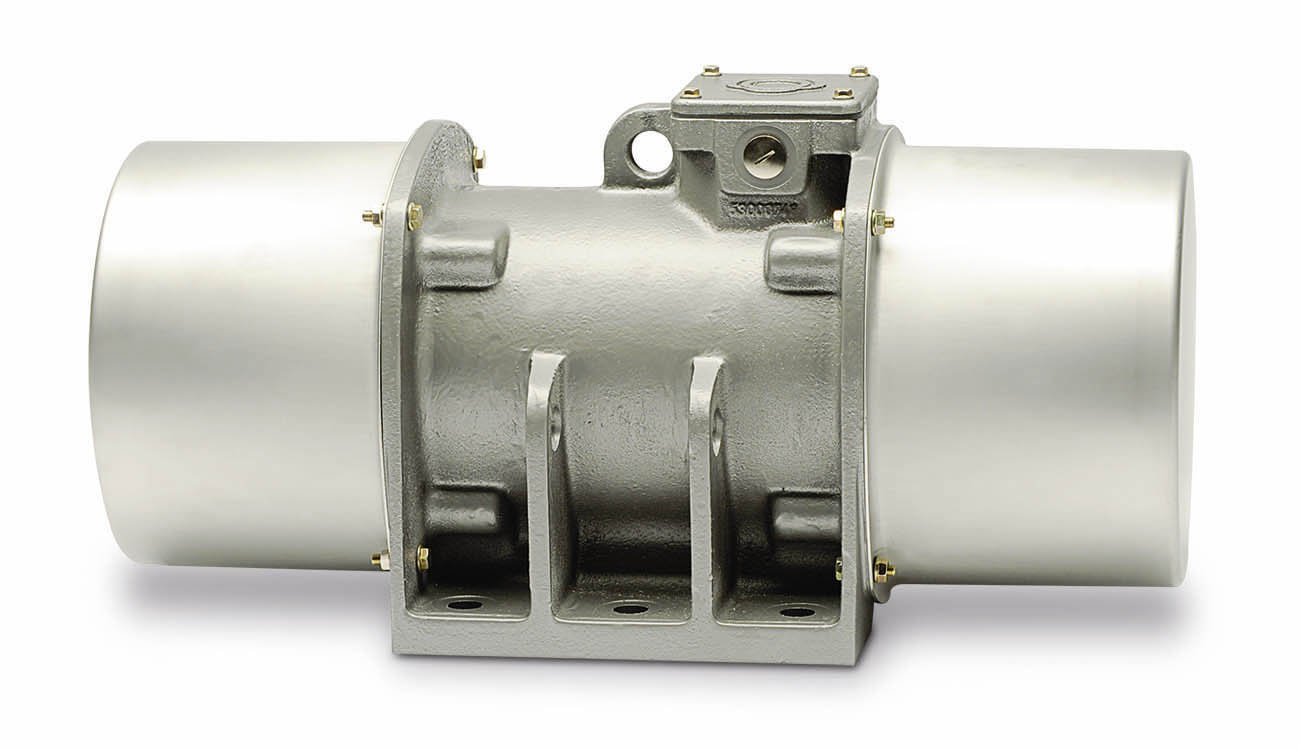

FRIEDRICH Vibrator Motor with Stainless Steel End Cover FHE-Type

FHE engines are equipped with stainless steel covers instead of covers made of powder-coated sheet metal deep drawing. The special shape and an O-ring seal made of silicone, ensure protection against the penetration of dust and water. The stainless steel hoods are available as an option for the entire program to motor size 7.

The motor housing is also coated in RAL 6011. Other colors are available on request. A special color of the motor housing with two-component Epoxy paint STEEL IT is available upon request. This Epoxy paint with particles of stainless steel INOX forms a very resilient coating. The non-toxic surface has a high resistance to chemicals, cleaning procedures, alkalis, food acids and UV rays. This coating is USDA approved.

Motors with stainless steel particle-color are equipped with stainless steel hoods and are particularly for use in the food, pharmaceutical and chemical industries.

General specifications

Power Supply:

Voltages from 115 V to 690 V at 50 Hz and 60 Hz available

Degree of Protection:

IP 66

Thermal class:

F (155 °C) according to DIN EN 60034-1

Tropical Insulation:

Standard

Electrical connection:

Use high flexible cable for heavy mechanical stress.Example: H07RN-F or A07RN-F according to DIN VDE 0282.

Permissible ambient temperature:

-20 to + 40 °C. Special versions with cold steel to -65 °C also available on request.

Operating mode:

Continuous operation (S1) and discontinuous operation at 100 % centrifugal force.

Hoods:

Hoods made from stainless steel, comprise the special shape. A silicone seal provides optimum protection against the ingress of dust and water.

Assembly:

Without limitation, motors can be mounted in any position.

Color coating:

Standard RAL 6011. Other colors available on request.

Type code:

The type code is read as follows:

First block number = working moment in kgcm (working moment = 2 x static moment)

This is followed by a hyphen and then the pole number.

Where: 4 = 1460 rpm 6 = 980 rpm (at 50 Hz mains frequency).

Behind the second dash, the size is specified.

- Anti-condensation heating

- Thermistor

- split end covers (see special catalog)

- Coupled motors (see special catalog)

- Special steel bearing retainer (see special catalog)

- Waterproof terminal box with a special sealant shed, connection cables with different Cable specifications in different lengths available.